1040 steel rockwell c hardness jominy end quench test|jominy end quench test : department Store The Jominy end-quench test is suitable for all steels except those of very low or very high hardenability, i.e., D1 6.0 in. The standard Jominy end-quench test cannot be used for highly alloyed air-hardened steels. 25 de out. de 2023 · Por Stefani Cavalcante, g1 Tocantins. 25/10/2023 14h20 Atualizado há 3 meses. Influencer Leandrinha faz pedido de namoro romântico. O Tocantins já foi .

{plog:ftitle_list}

WEBFale com a PVC Plast! Somos campeões de qualidade. Solicite nossas amostras e compare com a qualidade da concorrência. Nosso produto é visivelmente superior, tanto na impressão quanto no material! Produtos da linha. Também possuímos moldes prontos em várias medidas para atender as demandas mais comuns do mercado. Embalagens com .

Jominy-end quench test is now widely used for hardenabilities in the range of D I = 1 – 6 inches. For shallow-hardening steels (D I < 1 inch), as the quenched end of Jominy piece is not hardened fully, Grange proposed a hot-brine (H – B) test.This module provides a classroom lesson and a lab experiment for measurement of hardenability in a high-carbon steel according to, the Jominy End-Quench Test , (ASTM A255 – 10).The Jominy end-quench test is suitable for all steels except those of very low or very high hardenability, i.e., D1< 1.0 in. or D1> 6.0 in. The standard Jominy end-quench test cannot be used for highly alloyed air-hardened steels. A plain carbon steel and an alloy steel were assessed using the Jominy end quench test. The hardness of the samples was measured as a function of the distance from .

JOMINY - There are many varieties of steel - Engineers often need to control the hardness of a metal - Use the Jominy test to create a hardenability curve and identify necessary processing .Evaluate the hardenability of the steel used in this experiment using the plotted hardenability curve. Predict the microstructure of the steel all along the bar in correlation with your .One standard procedure that is widely used to measure hardenability of steel is the Jominy end-quench test. In this test water is sprayed on one end of a bar of steel while it is hot.The following charts present hardenability data for thirteen popular steels. They may be used to determine the approximate mid-radius hardness which is developed, in various sized rounds .

The Jominy test provides a measure of the ability of a steel to harden by transforming into martensite under set conditions, i.e., a measure of the hardenability of the steel. A standardised bar, 25.4 mm diameter and 102 mm .

This test can provide basic information on the hardenability of a material and be used for specifying incoming material for heat treatment. It can also be used to predict the expected hardness of an as-quenched heat . Several test samples of AISI 4140 steel were used for three experimental sets: heat-treated with the Jominy End-Quench Hardenability Test, fully tempered, and non-treated samples.3.1 This test method covers the procedure for determining the hardenability of steel by the end-quench or Jominy test. The test consists of water quenching one end of a cylindrical test specimen 1.0 in. in diameter and measuring the hardening response as a function of the distance from the quenched end. 4. Apparatus 4.1 Support for Test .The Jominy test, also referred to as Jominy end quench test, is a standardized method according to ISO 642 and ASTM A255 for determination of the hardenability of steel. Hardenability is the ability of the steel to increase .

maven test skip package

This document specifies a method for determining the hardenability of steel by end quenching (Jominy test) by using a test piece 25 mm in diameter and at least 100 mm long. . ISO 6508-1, Metallic materials — Rockwell hardness test — Part 1: Test method [3] JOMINY, W.E., .

Thermal Engineering of Steel Alloy Systems. T. Inoue, in Comprehensive Materials Processing, 2014 12.06.7 Jominy End Quenching 12.06.7.1 Jominy Test. The Jominy test, or Jominy end quench test, is known to evaluate the hardenability of steel in a simple way (64).The basic idea of the test and also the data obtained are used to understand the effects .Keywords: Cooling rate, Jominy end quench test, Steel, Hardenability, Rockwell hardness, Quenching. I. INTRODUCTION Hardenability of steel is said to be the tendency of the There are various scientific methods to measure hardenability of steel such as Grossman critical diameter method, Jominy end quench test, estimation of hardenability from chemical composition and .4340 steel. The Jominy End-Quench Test One standard procedure that is widely used to measure hardenability of steel is the Jominy end-quench test. In this test water is sprayed on one end of a bar of steel while it is hot. . Hardness (Rockwell C scale) measurements are taken for the first 2 ½ in. along each flat; for the first ½ in .

7. Take readings at an interval of 1/16 in. by measuring the Rockwell C hardness at each point marked in the previous step. 8. Plot the data for Rockwell Hardness versus Distance from quenched end as shown in Figure 3. Figure 3 Determining the Hardenability of a Material: In the Jominy test the quenching medium is eliminated from consideration

The Jominy test provides a measure of the ability of a steel to harden by transforming into martensite under set conditions, i.e., a measure of the hardenability of the steel. A standardised bar, 25.4 mm diameter and 102 mm long, is heated to the austenitising temperature and then placed on a rig in which one end of the rod is quenched by a . However, tempering and quenching are commonly not cost-effective for AISI 1040 carbon steel. Forging. AISI 1040 carbon steel can be forged at 982 to 1260°C (1800 to 2300°F). Hot Working. AISI 1040 carbon steel can be hot worked from 94 to 483°C (200 to 900°F ). Cold Working. AISI 1040 carbon steel can be cold worked in the annealed state .1040 (Continued) AS-QUencHeD RockweLL c HARDneSS 1/2” Rd . 1” Rd . 2” Rd . 4” Rd . water oil water oil water oil water oil Surface 54 28 50 23 50 B93 B98 B91 1/2 Radius 53 22 22 21 B97 B92 B96` B91 Center 53 21 18 18 B95 B91 B95 B89 MASS effect DAtA tensile Yield elongation Red . Area Brinell izod

Jominy end quench hardenability test - Download as a PDF or view online for free . In the test, a cylindrical steel sample is uniformly heated, then quenched at one end with water to rapidly cool it. . (15 thousandths of an inch) to remove decarburized material. specimen (heated to g phase field) 24°C water flat ground Rockwell C hardness .12.06.7 Jominy End Quenching12.06.7.1 Jominy Test. The Jominy test, or Jominy end quench test, is known to evaluate the hardenability of steel in a simple way (64). The basic idea of the test and also the data obtained are used to understand the .

Ramesh and Prabuh (2016) used aqueous polymeric solutions based on PAG in various concentrations to quench AISI 1040 steel, which has a composition very similar to that applied to the present work.depends primarily on the chemical composition of steel alloy [3]. The Jominy end quench technique is an experiment that is used to analyze the hardenability of substance using the Rockwell hardness test. Walter E. Jominy as well as A.L. Boegehold are the metallurgists behind the Jominy quench technique. They

In this study, the influence of thermal treatments on the properties of the martensitic stainless steel X30Cr13 (EN 10088-3: 1.4028) were investigated. These steels are characterized by a high hardness as well as corrosion .SAE 1040 steel standard Charpy type impact specimens will be used. 2) To study the effects of heat treatment on the microstructure and mechanical properties of steels; impact . Jominy End-Quench Test is a widely utilized standard test procedure for determining the hardenability of . the test bar and Rockwell C hardness measurements are made .The hardenability of a steel is defined as that property which determines the depth and . Rockwell C hardness measurements are then made every 2 mm and these readings are recorded. . Fig.1 Schematic illustration of the Jominy end-quench test Water spray . Title: Microsoft Word - jominy2006.doc

The Jominy end-quench test is the standard method to determine hardenabilty. The cylindrical specimen is heated to the austenitizing temperature. The bar is placed in the Jominy tank fixture, suspended by a bolt in the end. The other end is cooled .The most common test for studying these effects is the Jominy End Quench test. In this test a 140mm long and 25.4 mm in diameter sample is heated into the austenite range for selected temperatures and times and water spray quenched at one end, producing a varying cooling rate across the sample. Currently the Jominy End Quench test focuses more .Data from the Jominy end-quench test which is performed in Jominy test apparatus as shown in fig.2 can be used to determine whether particular steel can be sufficiently hardened in different quenching

Jominy test dimensioning Jominy test apparatus Used Jominy test-piece. Hardenability is the depth to which a steel is hardened after putting it through a heat treatment process. It should not be confused with hardness, which is a measure of a sample's resistance to indentation or scratching. [1] It is an important property for welding, since it is inversely proportional to .Figure 2: Quench rates at 704°C as a function of distance from the quenched end for the Jominy end quench. Figure 4: Range of Jominy end quench data for AISI 4140H. Data taken from [11]. Figure 3: Jominy end quench hardness data for several typical alloys. Data extracted from [11].

The Jominy End Quench Test The test sample is a cylinder with a length of 102 mm (4 inches) and a diameter of 25.4 mm (1 inch). The steel sample is normalised (to eliminate differences in .The Jominy End Quench Test ASTM A 255 measures Hardenability of steels. Hardenability is a measure of the capacity of a steel to be hardened in depth when quenched from its austenitizing temperature. Information gained from this test is necessary in selecting the proper combination of alloy steel and heat treatment to minimize thermal stresses and distortion when manufacturing .

Video clip 2: Quenching the sample; Video clip 3: Jominy end quench test; The test sample is a cylinder with a length of 102 mm (4 inches) and a diameter of 25.4 mm (1 inch). Jominy test specimen. The steel sample is normalised to eliminate differences in microstructure due to previous forging, and then austenitised. This is usually at a .

maven test package structure

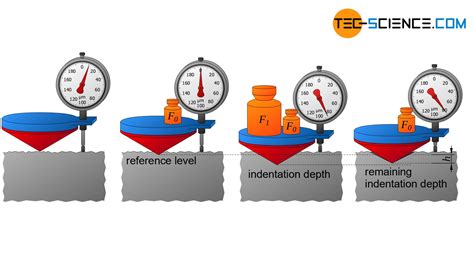

rockwell hardness test

知乎,中文互联网高质量的问答社区和创作者聚集的原创内容平台,于 2011 年 1 月正式上线,以「让人们更好的分享知识、经验和见解,找到自己的解答」为品牌使命。知乎凭借认真、专业、友善的社区氛围、独特的产品机制以及结构化和易获得的优质内容,聚集了中文互联网科技、商业、影视 .

1040 steel rockwell c hardness jominy end quench test|jominy end quench test